Content type: Industrial Design Project

Credits: Conrado Bergemann (Alumnus, MA Industrial Design, KABK, 2019)

Year: 2016-2019

Introduction:

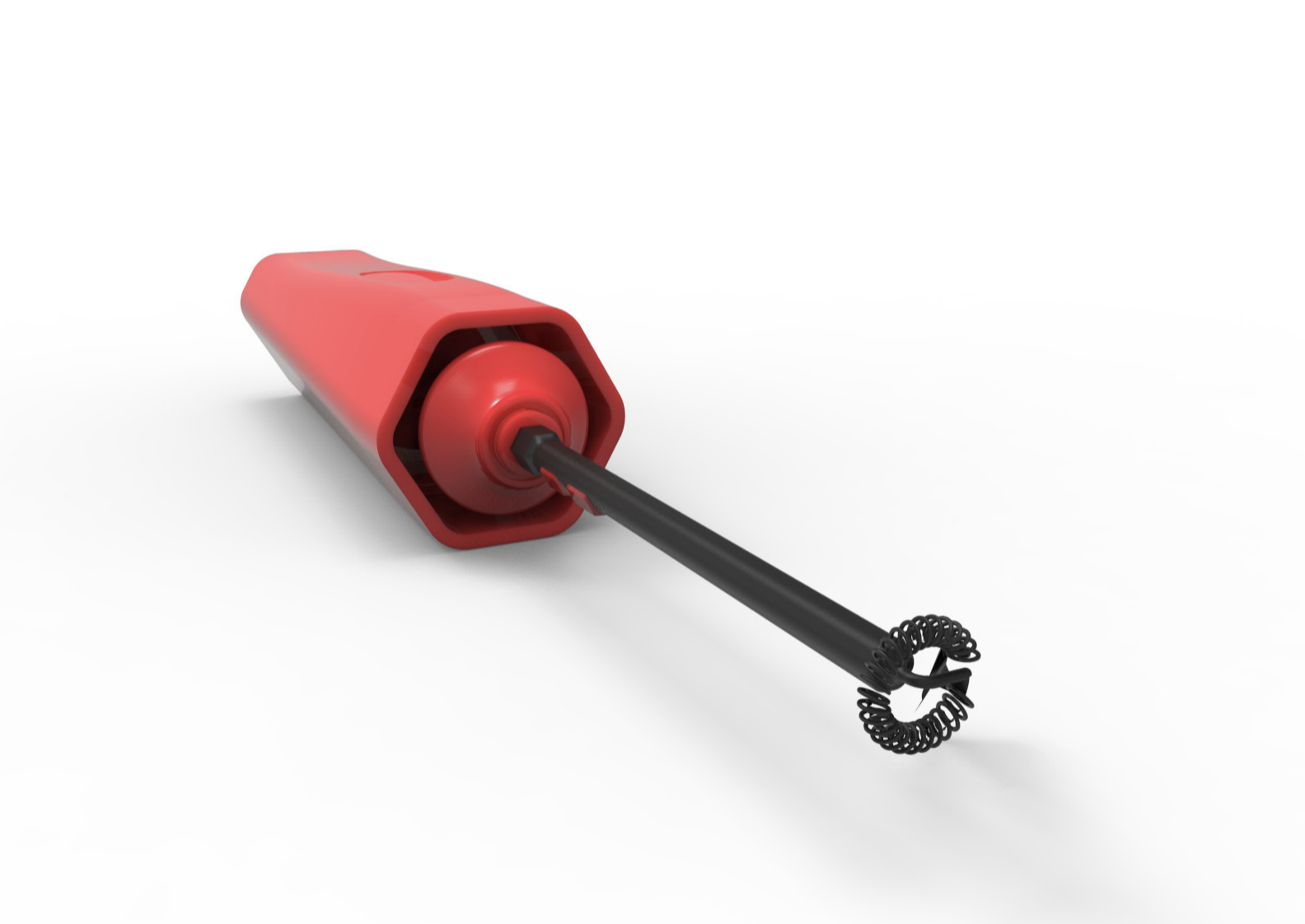

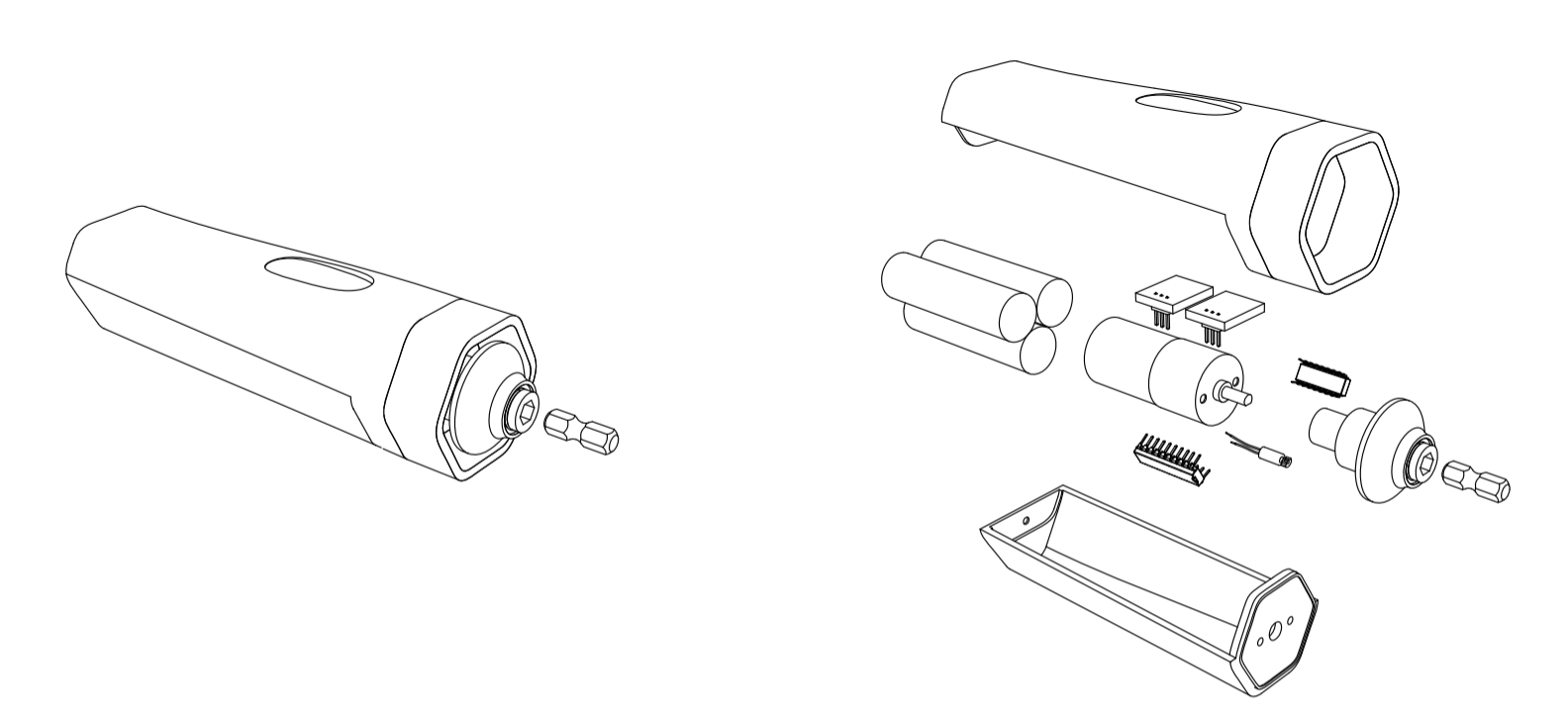

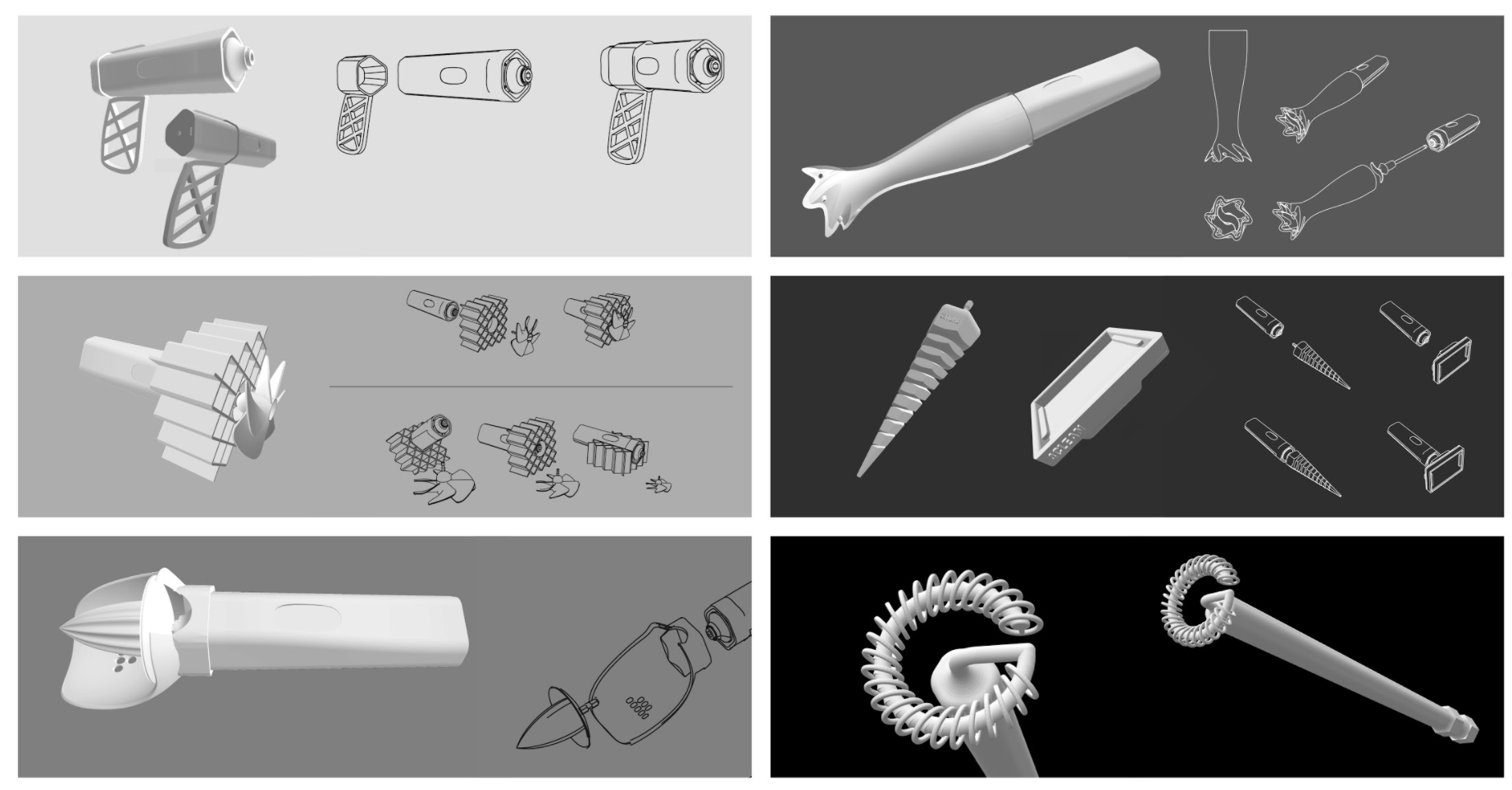

In the project Free to Alter: The Modular Motor Project, designer Conrado Bergemann explores modularity, waste, repairability, circular design and 3D printing. In an effort to eliminate the need for the unnecessary and repeated manufacture of hardware that often sits idle or is thrown out when one part breaks, Bergemann has made a modular multi-purpose domestic appliance. All that is needed is a single motor to which different appliances can be attached. This combination of modularity and accessibility means that the motor and the appliances are more repairable than if they were encased or black-boxed. Users can choose and print out parts from an open-source digital library.

Free to Alter